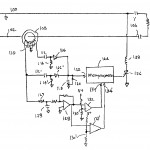

arc fault circuit interruptor diagram hand drawn showing diodes, resistors, micro processor, current transformer, capacitors, variable resistors, in an electrical ciruit, which is actually many circuits tied together, in parallel, showing the voltages on e

Arc fault circuit breakers stop fires before they ever start. They have an electronic pc board inside them that sense sparks, such as the fires caused by space heaters, or larger loads, such as heaters, motors, etc. We service oakland, Piedmont, Berkeley, Walnut creek and the surrounding areas. These can also save children who may inadvertently jam something into a plug or outlet.

This Arc fault circuit interruptor diagram is hand drawn showing diodes, resistors, micro processor, current transformer, capacitors, variable resistors, variable capacitors, and several other electronic and computer components, in an electrical circuit, which is actually many circuits tied together, in parallel, showing the voltages on the incoming hot leads as: neutral: 100 Hot: 102 Variable current transformer at 108 and 110, variable capacitor disconnect at 106 and 104 Microprocessor at 122, 124, 128, 134, and 136 off variable diode. Variable means that they can change due to the electrical circuit’s affects on these variable controls. They affect the energy incoming, the ( read) voltage and current, to detect a surging spark current, ie, a large spark which in reality outside this dreamers’ diagram, means that a space heater in your bedroom in catching the paper behind your bed on fire! This surging current spans the air gap to catch something on fire, or be in the process of catching it’s own electrical extension cord on fire in a tenants bedroom. The pc board (reads) this sparking current across that gap, set by manufacturers.

From Wikipedia:

Arc-fault circuit interrupter

An Arc Fault Circuit Interrupter (AFCI) is a circuit breaker designed to prevent fires by detecting an unintended electrical arc and disconnecting the power before the arc starts a fire. An AFCI must distinguish between a harmless arc that occurs incidental to normal operation of switches, plugs and brushed motors and an undesirable arc that can occur, for example, in a lamp cord that has a broken conductor in the cord.

Arc faults in a home are one of the leading causes for electrical wiring fires.[1] Each year in the United States, over 40,000 fires are attributed to home electrical wiring. These fires result in over 350 deaths and over 1,400 injuries each year.[2]

Conventional circuit breakers only respond to overloads and short circuits; so they do not protect against arcing conditions that produce erratic, and often reduced current. An AFCI is selective so that normal arcs do not cause it to trip. The AFCI circuitry continuously monitors the current and discriminates between normal and unwanted arcing conditions. Once an unwanted arcing condition is detected, the AFCI opens its internal contacts, thus de-energizing the circuit and reducing the potential for a fire to occur. An AFCI should not trip during normal arcing conditions, which can occur when a switch is opened or a plug is pulled from a receptacle.[3]

AFCIs resemble a GFCI/RCD (Ground-Fault Circuit Interrupt/Residual-Current Device) breaker in that they both have a test button although each has a different function. GFCIs and RCDs are designed to protect against electrical shock of a person, while AFCIs are primarily designed to protect against electrical fires caused by arcing. Some outlets must be protected by both a GFCI and an AFCI, such as an outlet near a wet bar in a family room.

Contents[hide] |

Electrical code requirements [edit]

Starting with the 1999 version of the National Electrical Code (NFPA 70) in the United States (US), and the 2002 version of the Canadian Electrical Code in Canada (CSA Standard C22.1), the national codes require AFCIs in all circuits that feed outlets in bedrooms of dwelling units. This requirement is typically accomplished by using a kind of circuit-breaker (defined by UL 1699) in the breaker panel that provides combined arc-fault and overcurrent protection. Not all US jurisdictions have adopted the AFCI requirements of the NEC as written.

The AFCI is intended to prevent fire from arcs. AFCI circuit breakers are designed to meet one of two standards as specified by UL 1699: “branch” type or “combination” type (note: the Canadian Electrical Code uses different terminology but similar technical requirements). A branch type AFCI trips on 75 amperes of arcing current from the line wire to either the neutral or ground wire. A combination type adds series arcing detection to branch type performance. Combination type AFCIs trip on 5 amperes of series arcing.

The advanced electronics inside an AFCI breaker detect sudden bursts of electric current in milliseconds; long before a standard circuit breaker or fuse would trip. A “combination AFCI breaker” will provide protection against parallel arcing (line to neutral), series arcing (a loose, broken, or otherwise high resistance segment in a single line), ground arcing (from line, or neutral, to ground), overload protection and short circuit protection.

In 2002, the NEC removed the word “receptacle”, leaving “outlets”, with the effect for lights and other wired-in devices such as ceiling fans within bedrooms of dwellings are added to the requirement. The 2005 code made it more clear that all outlets must be protected despite discussion in the code-making panel about excluding bedroom smoke detectors from the requirement. “Outlets” as defined in the NEC includes receptacles, light fixtures and smoke alarms, amongst other things.

As of January 2008, only “combination type” AFCIs will meet the NEC requirement. The 2008 NEC requires the installation of combination-type AFCIs in all 15 and 20 ampere residential circuits with the exception of laundries, kitchens, bathrooms, garages and unfinished basements.

Limitations [edit]

| This section does not cite any references or sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed.(July 2010) |

AFCIs are designed to protect against fires caused by electrical arc faults. While the sensitivity of the AFCIs helps in the detection of arc faults, these breakers can also indicate false positives, identifying normal circuit behaviors as arc faults. For instance, lightning strikes provide voltage and current profiles that resemble arc faults. This nuisance tripping reduces the overall effectiveness of AFCIs. Research into advancements in this area are being pursued.[4]

Also, AFCIs provide no specific protection against “glowing” connections, excess current, high line voltages or low line voltages. AFCI circuit breakers for use in a panelboard include a standard inverse-time circuit breaker. Glowing connections occur when relatively high electric current exists in a relatively large resistance object. Heat comes from power dissipation. This energy, when dissipated in a small junction area, can generate temperatures above 1000 degrees Celsius and can ignite most flammable materials.[5]

Bad wiring junctions can occur in utilization equipment, cords or in-situ wiring and especially in a defective switch, socket, plug, wiring connection and even at the circuit breaker or fuse panels. Terminal screws loosened by vibration, improper tightening or other causes offer increased resistance to the current, with consequent heating and potential thermal creep, which will cause the termination to loosen further and exacerbate the heating effect. In North America, high resistance junctions are sometimes observed at the terminations of aluminum wire circuits, where oxidation has caused increased resistance, resulting in thermal creep. No technology located in a circuit breaker or fuse panel could detect a high-resistance wiring fault as no measurable characteristic exists that differentiates a glow fault from normal branch circuit operation. Power Fault Circuit Interrupters (PFCI) located in receptacles are designed to prevent fires caused by glowing connections in premise wiring or panels. From the receptacle a PFCI can detect the voltage drop when high current exists in a high resistance junction. In a properly designed and maintained circuit substantial voltage drops should never occur. Proper wire terminations inside utilization equipment, such as appliances, and cords prevent high-resistance connections that could lead to fires.

An AFCI does not detect high line voltage due to an open neutral in a multiwire branch circuit. A multiwire branch circuit has both energized wires of a 120-240V split phase service. If the neutral is broken, devices connected from a 120 V leg to the neutral may experience excess voltage, up to twice normal.

AFCIs do not detect low line voltage. Low line voltage can cause electro-mechanical relays to repeatedly turn off (relay opens) and on (relay closes again). If current is flowing through the load contacts it will cause arcing across the contacts when they open. The arcing can oxidize, pit and melt the contacts. This process can increase the contact resistance, superheat the relay and lead to fires. Power fault circuit interrupters are designed to prevent fires from low voltage across loads.

Interference with power line networking [edit]

AFCIs may interfere with the operation of some power line communication technologies.[6]

External links [edit]

- Underwriters Labs summary on UL 1699 standard on AFCIs

- www.AFCIsafety.org – AFCI Educational Web site

- CPSC AFCI Fact Sheet

- AFCIs: Emerging Technology Solutions for Fires Resulting from Electrical Arcing from IAEI News: The Magazine

- CPSC AFCI Fact Sheet

- ^ 6 types of AFCIs are listed by Underwriters Laboratory

References [edit]

- ^ Lee, Douglas A.; Trotta, Andrew M.; King, William H. (Aug. 2000). “New Technology for Preventing Residential Electrical Fires: Arc-Fault Circuit Interrupters (AFCIs)”. Fire Technology (Kluwer Academic Publishers) 36 (3): 145–162.doi:10.1023/A:1015410726786. ISSN 0015-2684. Retrieved Feb. 26, 2013.

- ^ Ault, Singh, and Smith, “1996 Residential Fire Loss Estimates”, October 1998, U.S. Consumer Product Safety Commission, Directorate for Epidemiology and Health Sciences.

- ^ Source:”Arc Fault Circuit Interrupter (AFCI)FACT SHEET” accessed from http://www.cpsc.gov/CPSCPUB/PUBS/afcifac8.PDF, July 22, 2010

- ^ Stephenson, James, Ph.D. “Eliminating False Positives in the Detection and Location of sub 3ms Faults on AC/DC Lines” presented at the 2011 Aircraft Airworthiness & Sustainment Conference on April 19, 2011.

- ^ J.J. Shea, “Glowing Contact Physics,” IEEE Holm Conference on Electrical Contacts, Montreal, Canada, Sept. pp. 48-57, 2006.

- ^ A Work in Progress: Belkin Gigabit Powerline HD available at http://www.smallnetbuilder.com/lanwan/lanwan-reviews/30888-a-work-in-progress-belkin-gigabit-powerline-hd-starter-kit-reviewed?start=4

[gravityform id=”1″ name=”Williams Electric Contact Form” title=”false”]