Electric power, not only for cars, but for planes, boats, etc, is the future. Battery technology is the key. Conductive light weight nano infused plastic/lithium is coming any day.

Electric power, not only for cars, but for planes, boats, etc, is the future. Battery technology is the key. Conductive light weight nano infused plastic/lithium is coming any day.

This revolutionary breakthrough could help EVs drive 10 times longer before they need a recharge — here’s how

Laurelle Stelle

Fri, August 4, 2023 at 4:30 AM PDT·2 min read

“Big news in the world of car batteries: Researchers have discovered how to increase battery storage tenfold — perfect timing for the increasingly booming electric vehicle (EV) industry.”

Scientists at Pohang University of Science & Technology (POSTECH) found a way to multiply the energy storage of a battery by ten to create the ideal EV battery.

The part of a battery that stores power when charging and releases it during battery use is called the anode. Currently, most modern lithium batteries use an anode made of graphite.

Other materials, like silicon, have a higher energy capacity and would make more efficient batteries — but until now, researchers have been unable to create a stable battery with a silicon anode. This is because the reactions inside the battery cause the silicon to expand dangerously.

Professors Soojin Park and Youn Soo Kim of POSTECH, together with Professor Jaegeon Ryu of Sogang University, led a research team that solved this riddle. They created a binding material that will keep a high-capacity silicon anode from expanding, creating a stable lithium battery with at least ten times the capacity of one that uses a traditional graphite anode.

The POSTECH team is one of several working on advancing the world’s battery technology.

A Chinese company has produced an EV battery that uses cheap, abundant sodium instead of expensive lithium, and NASA is developing an improved solid-state battery that is smaller and lighter than traditional lithium ones. Another researcher is even creating biodegradable batteries from crab shells.

All of these advances make it easier to switch to non-polluting power sources because the most efficient clean energy types, like wind and solar, need batteries to work.

Burning fuel such as gasoline or coal produces energy on demand, but solar and wind only work when the weather allows. Providers need a way to store energy when the conditions are right so they can continue to offer it at night or when the wind dies down.

Meanwhile, EVs need to carry their power supply with them, so the more energy their batteries can hold, the further they can go — making their ranges competitive with gas-powered cars.

Professor Park summed up the discovery and the impact it could have in an announcement on the POSTECH website.

“The research holds the potential to significantly increase the energy density of lithium-ion batteries through the incorporation of high-capacity anode materials, thereby extending the driving range of electric vehicles,” he said. “Silicon-based anode materials could potentially increase the driving range at least tenfold.”

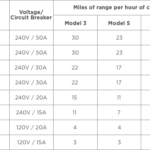

The first Tesla circuit I installed was for Malou Babilonia, in Berkeley, the original roadster model that cost about $150,000 back then, about 15 years ago. (2003) Top five ev charger level 2 240 volt electric vehicle chargers:

https://insideevs.com/news/341500/the-ultimate-buyers-guide-to-home-ev-chargers-plus-top-5-picks/

Her husband sold an internet bubble company and built an insanely gorgeous man cave house/garage, that was amazing. She had a painting of a Vietnamese worker, on hands and knees, on a hardwood floor, sanding the burned floor, lit by bright sun light coming through a window in the dark blue and burned floor, oil painting, and the worker wore a cone straw sun hat and had no shirt on. The predominant color was blue. I wanted to take a picture of it and copy it, but was not allowed to.

https://environmentcaliforniacenter.org/reports/cae/plugging-speeding-adoption-electric-vehicles-california-smart-local-policies

Every car vehicle truck suv sedan coupe bus plane will soon become electric and will need charging stations, 240 volt high amp circuit, and an oakland piedmont berkeley electrician to install them. When will this happen?: when very large and light weight batteries can flash charge in seconds and lose half their weight, and no longer be able to short out or explode. This advance in battery technology is not years but days away. The current technological blockage is the electrolyte, which uses fluid, heavy, inefficient, allows for short circuits, explosions, and toxicity to escape so limits lithium in fluid medium carrying current: currently a very heavy fluid medium.

We will eliminate fluid and replace it with current conducting lithium infused nano plastic. We get plastic to conduct by injecting nano bubbles of lithium infused with light weight inter-spursors. Then the plastic electrolyte can take way more lithium, 800% more to start with, without the attending explosive tendency of lithium when current is trans-versed with fluid. So even though we increase explosive lithium (when carried by fluid) it is no longer dangerous when used to in a non fluid plastic medium to massively conduct, so a massive amount of lithium and voltage and current amp flow can be used compared to current batteries. (Current flow is like your bath tub export. It’s the largest export hole in your house so more fluid can travel: which is: (analogous to more amps which is: current.)

Imagine the current battery export hole is a straw, and the future incoming plastic conducting export hole with be: a water tunnel drain! It’s the crappy batteries holding everyone back. But larger main electrical pge panels for ev electric vehicle electric car electrical panels increased size will be needed to handle electric vehicle flash charging thirst. Tesla is already offering close to 100 amp draws in their newer models. (That means your circuit feeding the tesla will have to be 100 amps! Commonly all a house has: in total: 100 amps.) So, we all will have to move up to 200 amp pge mains.

Electrician for automotive ev charging station oakland, electric car circuit, tesla circuit, ev electrician, electric car electrician installer, piedmont, berkeley ca. Tesla can swap out batteries in about 90 seconds. Most existing models use a 14-50 50 amp 240 volt nema circuit. Imo that ability will migrate to other ev car manufacturers such as electric car for: bmw, fiat, mercedes, honda, kia, lexus, infiniti, jaguar, nissan leaf, audi, honda, and all top ev cars and car chargers and charging stations that will take advantage of that quick change ability. Imo, future ev car battery chargers and car ev stations will use high amp, full voltage useage, faster and hotter charging. In order for that to be truly effective, the battery technology will have to come back home to full powered lithium, but without any fluid electrolyte. (Lithium currently reduced in a water electrolyte.) That will insist the electrolyte medium be a conductive plastic infused with air and way more lithium, in layers. That will increase the available voltage and power per gram of weight 3 times over the current battery weight. Less weight, more power will enable clients to install higher ampacity, ie, imo we will use 100 amp circuits that will “flash charge” with much faster, much more efficient transfer of power to the new medium at a level two charger of 240 volts at 100 amps…. It will also remove the possibility of the battery being able to short out during accidents and explode. It will also enabel larger trucks and delivery vehicles, and buses to become electric vehicles.

The reason why chargers take so long now, is a combination of the less efficient and watery bad electrolyte, and the lower amp capability and draw of the medium. Small amps at low power, ie, level one, at 120 volts, and low amps, in a low carry medium, means very long and inefficient charge times. (Also 120 volts has to fight through the neutral and ground back to the power company, so it costs more to pay for it rather than two hot strand 240 volt which is less impedance to current flow as there is no ground or neutral, just I squared R loss, aluminum back to power plant cost.)

The level two js 1227 common charger cables will have to now carry 100, not 50 amps. Imo, that will demand that pge clients install larger pge panels, and change federal pacific, sylvania zinsco, knob and tube fuse panels, and older pge main panels, and install larger residential sub panels, to accommodate the higher amp “flash” charge. So anyone currently changing their panel, and putting in smaller panel pge mains, will inevitably have to redo that panel in a matter of imo, five years from now I estimate. This will also demand a lot more lithium, plastic, and copper to be made. A consequence of larger ev charger power draws is, larger draws on the power company grids, at night, when people will plug into the grid.

That will enable future upgrading of: power, back up, distance, and recharging, charger for the tesla and competitors….. This page tells you how long it takes to recharge: https://www.pluglesspower.com/learn/tesla-model-s-charging-home-public-autonomously/

tesla electric car circuit upside down[/caption]

tesla electric car circuit upside down[/caption]

Find electrician, electrical contractor, licensed electrician, for electric car circuit, oakland, Piedmont, berkeley, , tesla electric car circuit, bmw electric car, ford fusion, Mercedes B class electric car, Volkswagen e-up electric car circuit, e-golf electric car circuit, electric car, Hyundai ioniq electric car circuit, electric car circuuit, hyundai, kona, Mitsubishi i-miev, chevy bolt, nissan leaf, bmw electric car circuit, electrical contractor expert electric car installation. Professional electric car charger installation expert in Oakland, piedmont, berkeley area. Experienced, licensed, bonded, insured, master, best electrician will install your Electric vehicle charger and nema outlet for the right ev circuit for every electric vehicle or car or suv. We correctly install all charging system and electric car chargers for any electric car. We correnctly install residential EV chargers and work on commercial jobs also. Our company has extensive experience with EV and charger installation circuits, as the first one I isntalled was for a tesla sports car about 15 years ago. I don’t not use subcontractors or illegal helpers.

Williams Electric is located in Oakland, CA. We have comprehensive experience working with all permit departments in the east bay area. I am familiar with the documentation necessary to comply with state, local and federal rules of installation and nec code. This shot is of an electric car charging charger, circuit, a tesla 50 amp 240 volt, line installed upside down.

There are lots of options in the EVSE business. If you want a plug-in unit, I recommend that it be both 50 amp capable, PORTABLE, and able to handle 100-264 volts.

file:///C:/Users/g/Documents/NEMA_simplified_pins.svg