[metaslider id=1593]

What should our clients expect during a 200 amp pg&e power panel upgrade or main panel change?

What should our clients expect during a 200 amp pg&e power panel upgrade or main panel change?

Recently, a client, Kenya Jones, had her pg&e power destroyed by a neighbors redwood tree, which fell over in the heavy rain. We had done some work for her in the past, in lighting, led landscaping. Now her entire power system, panel, conduit, and the pg&e line was fried and ripped off her house by the falling tree. The panel had caught fire, and the pg&e t man crew removed the drop to the other side of the street, on way up high to the cross bar. She called us in the morning. By that evening, I had gone out to her house, seen the devastation, taken a short video, gotten the city of Oakland to issue a permit (just try to do that on your own!), gotten pg&e to issue a rep ( just try to do that on your own!), gotten the rep to issue a COD letter (just try to do that on your own!), and gotten the city to issue an inspection for the next morning! The inspector came out the very next morning after Kenya called us, and passed the job although I had not finished the conduit run yet!

The city admin person knew us, the pg&e rep knew us, and the city inspector knew us. Kenya’s neighbor, the one who was responsible for the falling tree, denied responsibility for it, and her power was also cut off. She hired a cut rate electrician, and her power has still not been restored weeks later. (Staying in a hotel room). Due to her mistreatment of my client, I declined to work for her. Sometimes people try to hire us, who are not as nice as Kenya!

So, do you want a guy to do your panel, who has a few panel changes under his belt, or do you want a guy, with two thousand five hundred panel changes? I know every piece of material, every thing the inspectors want us to do, everything pg&e wants us to do, two thousand times over! I know what not to do. I’ve learned from mistakes I’ve made, the wrong tools, the wrong ladder, the wrong materials, cheap materials versus bullet proof. Think back in your own work, and remember how you were, when you only had a few jobs under your belt, and how you are now, with thousands of jobs you have completed. This is not a normal job. One bad mistake, and a client can be hurt, burned, electrocuted, or die. There are too many guys out there, who hire guys off the street who really don’t know what to do.

Power Cut Off

Power will be cut off soon after work begins, the morning of the scheduled start day. The existing panel will be removed, and power will be available to all other trades on the job who request it. Some noise and dirt will be created during the change over. Freezer and refrigerators will not be affected. No food will be spoiled or lost. A GFI breaker can be temporarily installed on the hot PG&E line.

———————————————————————————————————————————————–

Old System Removed

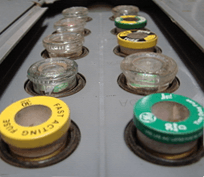

Electrical Fuse Panel

The old system, its metal riser, the metal panel, the fuses or old breakers will be removed and recycled with the city. Nothing will be left for the client to worry about removing, or paying for a dump run. Williams Electric will take a video or picture of all debris at the end of the inspection, so the inspector or pg&e rep may see the old system if requested. Patching may be required.

———————————————————————————————————————————————–

New System Will Be Installed

The new panel will be placed on the surface of the building, and the new metal riser will be surface mounted as well. Any eave penetration will be roof jacked and rain proofed. We will use copper wire, and not the fire prone aluminum wire. Many electricians use aluminum to raise profits. The new grounding system will consist of an 8’ ground rod, a main water bond, an inter system bonding bridge, and a hot-cold-gas bond at the water heater. Upon inspection, the water heater and main water bond will need to be seen by inspector, so access must be granted to this ahead of time.

————————————————————————————————————————————————–

The Size of The New System

The Size of The New System

The size of the new system will be most likely, 100- 200 amps, 240 volts, with 12/24 distribution. Some may ask for 200 amps due to electric car addition to loads, etc, 20/40 distribution, for more ampacity and more circuit breaker expansion. We sometimes install 100 amps, as that is only the minimum size allowable by the NEC. The grounding wire will be either a #6 or a #4 size and will be exposed to the ground rod. The advantage given by 200 amp systems is mainly for electric car or remodel, future expansions, with more breakers available. In the trade we call this: distribution, and main panels should almost always include extra spots for future breakers, which we call: distribution. These breakers distribute power in smaller branch circuits, ie, to kitchens, AC, electric cars, hot tubs, saunas, remodels, sub panels, refrigerators, micro waves, etc.

Most will need more than 125 amps, if adding electric car circuits. Larger homes may justify the addition of 200 amp mains with more distribution.

————————————————————————————————————————————————–

Inspections by the City and PG&E

Before any work is started, we will obtain a permit with the city and fill out an application with PG&E re: the main panel change. If a remodel is being done, or load is being added to the line, or a larger panel is being installed, or the drop is being moved, PG&E may ask the owner to pay for a larger drop. (If a load calculation shows that the load existing, or being added, does not exceed the current pg&e drop sized, the pg&e riser, and current ampactity wire, does not have to be matched to the new ampacity of the new panel!) After the city permit is obtained, the work will be done. Several days after the job is done, Ronda will call for inspection with the city. The city will give us a two hour window, during which time she will wait for the city inspector to show. Some do not show up on time. Access will be required to the building and the crawl space during that 2 hour window. Ronda will open the panels for the inspector and show the grounding as well. After the job passes with the city, the city inspector will fax a clearance sheet to PG&E. PG&E will then send out their own inspector, who will only need to look at the exterior work. PG&E will then send out a T-man crew (Termination man crew). The crew will permanently crimp our temporary connection at the weather head with a hydraulic crimp tool. The power will at this time be cut by PG&E for 20 minutes. They do not notify us or you during the crimp. Any branches resting on the PG&E drop will need to be trimmed by the property owner before the crimp can be done. If PG&E does not send the T-man crew, we will need to remind them, and the owner will need to notice if the weather head connection has not been crimped by PG&E (Our connection is only intended to be temporary).

————————————————————————————————————————————————–

What is the owner responsible for?

PG&E owns the meter, and the drop. The owner is responsible for the panel, the riser, the tree branches, the weather head, the wire in the conduit and the panel wiring and any patching. If the drop connection crimp goes bad, this is PG&E’s responsibility. If the drop or the panel is injured by a tree, it is the owner’s responsibility to fix it.

[metaslider id=1593]

[gravityform id=”1″ name=”Williams Electric Contact Form” title=”false”]